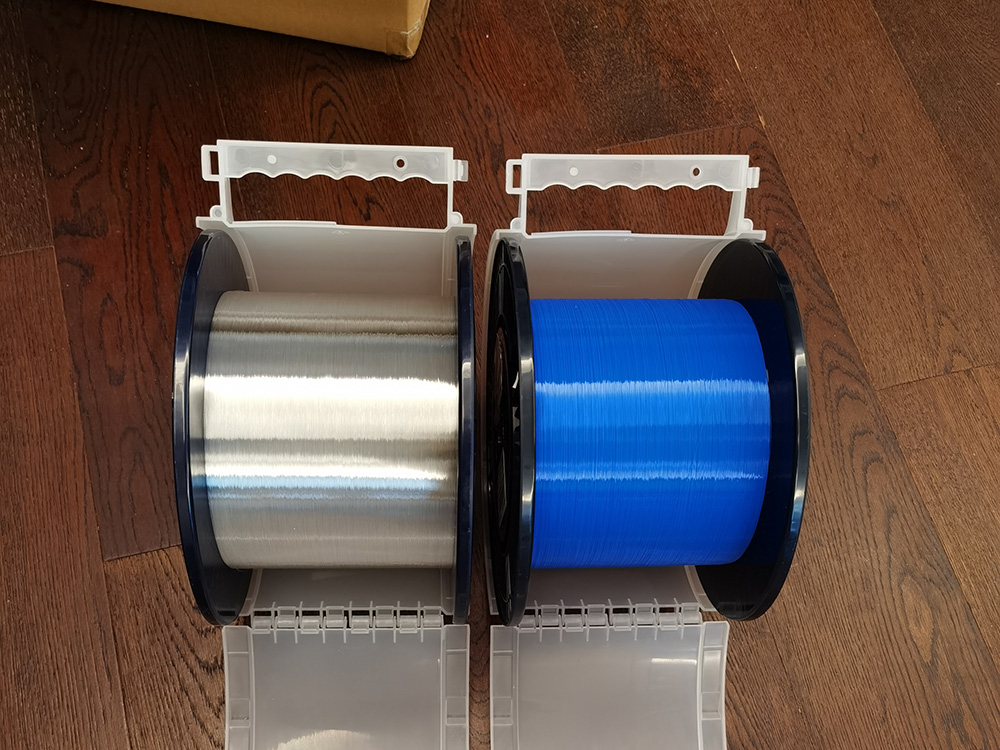

QFRP with 0.56mm Dia.

Inspection Status List

S/N |

Testing item |

Conclusion |

1 |

Appearance |

Qualified |

2 |

Outer diameter deviation |

Qualified |

3 |

Tensile strength |

Qualified |

4 |

Tensile modulus of elasticity |

Qualified |

5 |

Elongation at break |

Qualified |

6 |

High temperature bending performance |

Qualified |

7 |

Low temperature bending performance |

Qualified |

Test result

S/N |

Testing item |

Unit |

Standards and Requirements |

Test result |

Conclusion |

||||||

1 |

Appearance |

-- |

The color is uniform and consistent, with no cracks or burrs on the surface, and a smooth feel |

The color is uniform and consistent, with no cracks or burrs on the surface, and a smooth feel |

Qualified |

||||||

|

1) Testing method According to: YD/T 1181.1-2015 4.1.1 | |||||||||||

|

2) date, environmental conditions, location

| |||||||||||

|

3) Testing equipment

| |||||||||||

Test result

S/N |

Testing item |

Unit |

Standards and Requirements |

Test result |

Conclusion |

||||||

2 |

Diameter deviation |

mm |

±0.02 |

-0.01 |

Qualified |

||||||

|

1) Testing method According to: YD/T 1181.1-2015 5.2 | |||||||||||

|

2) date, environmental conditions, location

| |||||||||||

|

3) Testing equipment

| |||||||||||

Test result

S/N |

Testing item |

Unit |

Standards and Requirements |

Test result |

Conclusion |

|||||||||

3 |

Tensile strength |

MPa |

≥1600 |

1711 |

Qualified |

|||||||||

4 |

Tensile modulus of elasticity |

GPa |

≥52 |

60.1 |

Qualified |

|||||||||

5 |

Elongation at break |

-- |

-- |

2.5% |

Reference item |

|||||||||

|

1) Testing method According to: YD/T 1181.3-2011 5.6 | ||||||||||||||

|

2) date, environmental conditions, location

| ||||||||||||||

|

3) Testing equipment

| ||||||||||||||

Test result

S/N |

Testing item |

Unit |

Standards and Requirements |

Test result |

Conclusion |

|||||||||

6 |

High temperature bending performance |

-- |

No cracks or burrs on the surface, no bending, no disassembly, and a smooth feel |

No cracks or burrs on the surface, no bending, no disassembly, and a smooth feel |

Qualified |

|||||||||

|

1) Testing method According to: YD/T 1181.3-2011 5.7 2) Sample condition: Bending radius: 14.4 mm (30 times the nominal outer diameter), number of turns: 3 turns; High temperature treatment conditions: 80℃±2℃, 24h | ||||||||||||||

|

2) date, environmental conditions, location

| ||||||||||||||

|

3) Testing equipment

| ||||||||||||||

Test result

S/N |

Testing item |

Unit |

Standards and Requirements |

Test result |

Conclusion |

|||||||||

7 |

Low temperature bending performance |

-- |

No cracks or burrs on the surface, no bending, no disassembly, and a smooth feel |

No cracks or burrs on the surface, no bending, no disassembly, and a smooth feel |

Qualified |

|||||||||

|

1) Testing method According to: YD/T 1181.3-2011 5.8 2) Sample condition: Bending radius: 14.4 mm (30 times the nominal outer diameter), number of turns: 3 turns; Low temperature treatment conditions: -40℃±2℃, 24h | ||||||||||||||

|

2) date, environmental conditions, location

| ||||||||||||||

|

3) Testing equipment

| ||||||||||||||