Optical Fiber OM4

Reference

| ITU-T G.651.1 | Characteristics of a 50/ 125 μm multimode graded index optical fibre cable for the optical access network |

| IEC 60794- 1- 1 | Optical fiber cables-part 1- 1: Generic specification- General |

| IEC 60794- 1-2 IEC 60793-2- 10 | Optical fibres – Part 2- 10: Product specifications – Sectional specification for category A1 multimode fibres |

| IEC 60793-1-20 | Optical fibers - part 1-20: Measurement methods and test procedures – Fibre geometry |

| IEC 60793- 1-21 | Optical fibres – Part 1-21: Measurement methods and test procedures – Coating geometry |

| IEC 60793- 1-22 | Optical fibres – Part 1-22: Measurement methods and test procedures – Length measurement |

| IEC 60793- 1-30 | Optical fibres - Part 1-30: Measurement methods and test procedures - Fibre proof test |

| IEC 60793- 1-31 | Optical fibres - Part 1-31: Measurement methods and test procedures - Tensile strength |

| IEC 60793- 1-32 | Optical fibres - Part 1-32: Measurement methods and test procedures - Coating strippability |

| IEC 60793- 1-33 | Optical fibres – Part 1-33: Measurement methods and test procedures – Stresse corrosion susceptibility |

| IEC 60793- 1-34 | Optical fibres - Part 1-34: Measurement methods and test procedures - Fibre curl |

| IEC 60793- 1-40 | Optical fibres - Part 1-40: Measurement methods and test procedures - Attenuation |

| IEC 60793- 1-41 | Optical fibres - Part 1-41: Measurement methods and test procedures - Bandwidth |

| IEC 60793- 1-42 | Optical fibres - Part 1-42: Measurement methods and test procedures - Chromatic dispersion |

| IEC 60793- 1-43 | Optical fibres - Part 1-43: Measurement methods and test procedures - Numerical aperture |

| IEC 60793- 1-46 | Optical fibres - Part 1-46: Measurement methods and test procedures - Monitoring of changes in optical transmittance |

| IEC 60793- 1-47 | Optical fibres - Part 1-47: Measurement methods and test procedures - Macrobending loss |

| IEC 60793- 1-49 | Optical fibres - Part 1-49: Measurement methods and test procedures - Differential mode delay |

| IEC 60793- 1-50 | Optical fibres - Part 1-50: Measurement methods and test procedures - Damp heat (steady state) |

| IEC 60793- 1-51 | Optical fibres - Part 1-51: Measurement methods and test procedures - Dry heat |

| IEC 60793- 1-52 | Optical fibres - Part 1-52: Measurement methods and test procedures -Change of temperature |

| IEC 60793- 1-53 | Optical fibres - Part 1-53: Measurement methods and test procedures - Water immersion |

Product Introduction

MultiCom ® bending insensitive OM3-300 is a type of 50/ 125 graded index multimode optical fiber. This optical fiber, providing lower DMD and attenuation, is specifically designed for 10 Gb/s Ethernet with a low-cost 850 nm VCSEL as the light source. Bending insensitive OM3-300 multimode optical fibers meet or exceed the ISO/IEC 11801 OM3 technical specifications and A1a.2 type of optical fibers in IEC 60793-2- 10.

Application Scenarios

LAN, DC, SAN, COD and other areas

1G/ 10G/40G/ 100G network

10 Gb/s network with transmission distance up to 300 m

Performance Features

High bandwidth and low attenuation

Excellent bending resistance designed for low cost 850 nm VCSEL 10 Gb/s Ethernet

Excellent bending resistance designed for low cost 850 nm VCSEL 10 Gb/s Ethernet

Product Specification

| Parameter | Conditions | Units | Value |

| Optical | |||

| Attenuation | 850 nm | dB/km | ≤2.4 |

| 1300 nm | dB/km | ≤0.6 | |

| Bandwidth (Overfilled Launch) | 850 nm | MHz.km | ≥3500 |

| 1300 nm | MHz.km | ≥500 | |

| Effective Mode Bandwidth | 850 nm | MHz.km | ≥4700 |

| 10G Ethernet SR | 850 nm | m | 300 |

| 40G Ethernet( 40GBASE-SR4) | 850 nm | m | 100 |

| 100G Ethernet( 100GBASE-SR10) | 850 nm | m | 100 |

| Numerical Aperture | 0.200±0.015 | ||

| Zero Dispersion Wavelength | nm | 1295- 1340 | |

| Effective Group Refractive Index | 850 nm | 1.482 | |

| 1300 nm | 1.477 | ||

| Attenuation Nonuniformity | dB/km | ≤0.10 | |

| Partial Discontinuity | dB | ≤0.10 | |

| Geometrical | |||

| Core Diameter | μm | 50.0±2.5 | |

| Core Non-Circularity | % | ≤5.0 | |

| Cladding Diameter | μm | 125±1.0 | |

| Cladding Non-Circularity | % | ≤1.0 | |

| Core/Cladding Concentricity Error | μm | ≤1.0 | |

| Coating Diameter (Uncolored) | μm | 245±7 | |

| Coating/Cladding Concentricity Error | μm | ≤10.0 | |

| Environmental (850nm, 1300nm) | |||

| Temperature Cycling | -60℃ to +85℃ | dB/km | ≤0.10 |

| Temperature Humidity Cycling | - 10℃ to +85℃ up to 98% RH | dB/km | ≤0.10 |

| High Temperature & High Humidity | 85℃ at 85% RH | dB/km | ≤0.10 |

| Water Immersion | 23℃ | dB/km | ≤0.10 |

| High Temperature Aging | 85℃ | dB/km | ≤0.10 |

| Mechanical | |||

| Proof Stress | % | 1.0 | |

| kpsi | 100 | ||

| Coating Strip Force | Peak | N | 1.3-8.9 |

| Average | N | 1.5 | |

| Dynamic Fatigue (Nd) | Typical Value | ≥20 | |

| Macrobending Loss | |||

| R15 mm×2 t | 850 nm 1300 nm | dB dB | ≤0.1 ≤0.3 |

| R7.5 mm×2 t | 850 nm 1300 nm | dB dB | ≤0.2 ≤0.5 |

| Delivery Length | |||

| Standard Reel Length | km | 1.1- 17.6 | |

Optical fiber test

During manufacturing period, all the optical fibers shall be tested in accordance with the following test method.

| Item | Test method |

| Optical characteristics | |

| Attenuation | IEC 60793- 1-40 |

| Change of optical transmission | IEC60793- 1-46 |

| Differential mode delay | IEC60793- 1-49 |

| Modal bandwidth | IEC60793- 1-41 |

| Numerical aperture | IEC60793- 1-43 |

| Bending loss | IEC 60793- 1-47 |

| Chromatic dispersion | IEC 60793- 1-42 |

| Geometrical characteristics | |

| Core diameter | IEC 60793- 1-20 |

| Cladding diameter | |

| Coating diameter | |

| Cladding non-circularity | |

| Core/cladding concentricity error | |

| Cladding/coating concentricity error | |

| Mechanical characteristics | |

| Proof test | IEC 60793- 1-30 |

| Fiber curl | IEC 60793- 1-34 |

| Coating strip force | IEC 60793- 1-32 |

| Environmental characteristics | |

| Temperature induced attenuation | IEC 60793- 1-52 |

| Dry heat induced attenuation | IEC 60793- 1-51 |

| Water immersion induced attenuation | IEC 60793- 1-53 |

| Damp heat induced attenuation | IEC 60793- 1-50 |

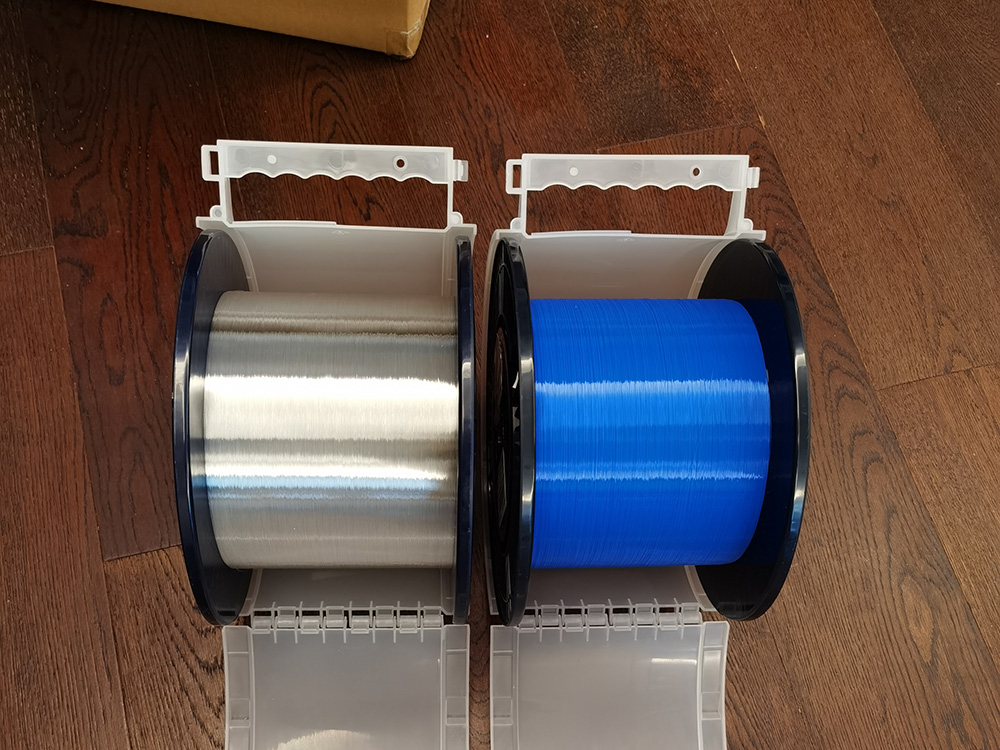

Packing

4. 1 Optical fiber products shall be disk-mounted. Each disc can only be one manufacturing length.

4.2 Cylinder diameter should not be less than 16cm. Coiled optical fibers should be neatly arranged, not loose. Both ends of the optical fiber shall be fixed and its inner end shall be fixed. It can store more than 2m optical fiber for inspection.

4.3 The optical fiber product plate shall be marked as follows: A) Name and address of the manufacturer;

B) Product name and standard number;

C) Fiber model and factory number;

D) Optical fiber attenuation;

E) Length of optical fiber, m.

4.4 Optical fiber products shall be packaged for protection, and then put into the packaging box, on which shall be marked:

A) Name and address of the manufacturer;

B) Product name and standard number;

C) Factory batch number of optical fiber;

D) Gross weight and package dimensions;

E) Year and month of manufacture;

F) Packing, storage and transportation drawings for wetness and moisture resistance, upward and fragile.

Delivery

Transport and storage of optical fiber should pay attention to:

A. Store in a warehouse with room temperature and relative humidity less than 60% awayfrom light;

B. Optical fiber discs shall not be laid or stacked; Copyright @2019, All right reserved. Page 5 of 6;

C. Awning should be covered during transportation to prevent rain, snow and sun exposure. Handling should be careful to prevent vibration.