Specification Of Optical Fiber (G.652D)

QUALITY

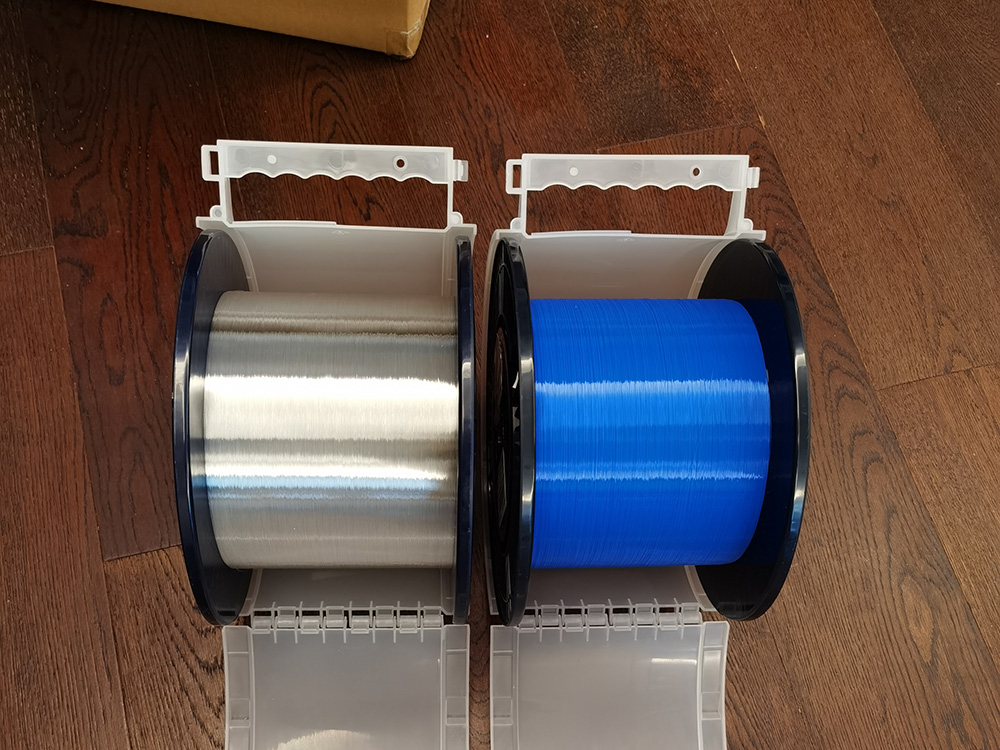

Fiber coating should be free from cracks, splits, bubbles, spicks etc. winding should be uniform on the spool.

MATERIAL

Doped silica / silica with double layered UV curable resin.

Product Specification

| Sr. No. | Parameters | UoM | Values |

| 1 | Attenuation | ||

| 1.1 | At 1310 nm | dB/km | ≤0.340 |

| 1.2 | At 1550 nm | ≤0.190 | |

| 1.3 | At 1625 nm | ≤0.210 | |

| 1.4 | At 1383±3 nm | ≤value at 1310nm | |

| 1.5 | Attenuation deviation within 1525~1575nm range (Ref. 1550nm wavelength) | dB | ≤0.05 |

| 1.6 | Attenuation deviation within 1285~1330nm range (Ref. 1310nm wavelength) | ≤0.05 | |

| 2 | Chromatic Dispersion | ||

| 2.1 | 1285~1330 nm wavelength range | ps/nm.km | ≤3.5 |

| 2.3 | At 1550 nm | ≤18 | |

| 2.4 | At 1625 nm | ≤22 | |

| 2.5 | Zero Dispersion Wavelength | Nm | 1300 to 1324 |

| 2.6 | Dispersion Slope at zero dispersion wavelength | nm^2.km | ≤0.092 |

| 3 | PMD | ||

| 3.1 | PMD at 1310 nm & 1550 nm (individual fiber) | ps/sqrt.km | ≤0.10 |

| 3.2 | Link PMD | ≤0.06 | |

| 4 | Cut off Wavelength | ||

| A | Fiber cut off wavelength range | Nm | 1100~1320 |

| B | Cable cut off wavelength | ≤1260 | |

| 5 | Mode Field Diameter | ||

| 5.1 | At 1310 nm | µm | 9.2±0.4 |

| 5.2 | At 1550 nm | 10.4±0.5 | |

| 6 | Geometrical Properties | ||

| 6.1 | Coating Diameter (un-colored fiber) | µm | 242±5 |

| 6.2 | Cladding Diameter | 125±0.7 | |

| 6.3 | Core Concentricity Error | ≤0.5 | |

| 6.4 | Cladding Non-circularity | % | ≤0.7 |

| 6.5 | Coating-Cladding Concentricity | µm | ≤12 |

| 6.6 | Fiber Curl (radius of Curvature) | Mtr. | ≥4 |

| 6.7 | Refractive Index profile | Step | |

| 6.8 | Effective group index of Refraction Neff@1310nm (typ.) | 1.4670 | |

| 6.9 | Effective group index of Refraction Neff@1550nm (typ.) | 1.4681 | |

| 7 | Mechanical Properties | ||

| 7.1 | Proof test for min. strain level & Duration of test | kpsi.sec | ≥100 |

| 7.2 | Change in Attenuation with Bending (Micro-bend) | ||

| a | 1 turn on 32mm Dia. Mandrel at 1310 & 1550 nm | dB | ≤0.05 |

| b | 100 turn on 60mm Dia. Mandrel at 1310 & 1550 nm | ≤0.05 | |

| 7.3 | Strippability Force to remove primary coating | N | 1.0≤F≤8.9 |

| 7.4 | Dynamic Tensile Strength (0.5~10 mtr. Unaged fiber) | kpsi | ≥550 |

| 7.5 | Dynamic Tensile Strength (0.5~10 mtr. Aged fiber) | ≥440 | |

| 7.6 | Dynamic Fatigue | ≥20 | |

| 8 | Environmental Properties | ||

| 8.1 | Induced attenuation at 1310 & 1550 nm Temp. & Humidity cycle from -10℃ to +85℃ at 98% RH (Ref. temp 23℃) | dB/km | ≤0.05 |

| 8.2 | Induced attenuation at 1310 & 1550 nm Temp. cycle from -60℃ to +85℃ (Ref. temp 23℃) | ≤0.05 | |

| 8.3 | Induced attenuation at 1310 & 1550 nm for Water Immersion at 23±2℃ | ≤0.05 | |

| 8.4 | Induced attenuation at 1310 & 1550 nm for Accelerated Ageing at 85±2℃ (Ref. temp 23℃) | ≤0.05 | |

PACKING

Prior approval of packing dimensions should be taken before dispatch.