G.657.A1. Bending Insensitive Single-mode Optical Fiber

Application Scenarios

Performance Features

Product Specification

| Parameter | conditions | Units | value |

| Optical | |||

| Attenuation | 1310 nm | dB/km | ≤ 0.350 |

| 1383 nm | dB/km | ≤ 0.350 | |

| 1550 nm | dB/km | ≤ 0.210 | |

| 1625 nm | dB/km | ≤ 0.230 | |

| Attenuation vs. Wavelength | 1310 nm VS. 1285- 1330 nm | dB/km | ≤ 0.04 |

| 1550 nm VS. 1525- 1575 nm | dB/km | ≤ 0.03 | |

| Zero Dispersion Wavelength | - | nm | 1300 - 1324 |

| Zero Dispersion Slope | ps/(nm2 ·km) | 0.073 - 0.092 | |

| Dispersion | 1550nm | ps/(nm ·km) | 13.3- 18.6 |

| 1625nm | ps/(nm ·km) | 17.2-23.7 | |

| Polarization Mode Dispersion (PMD) | - | ps/√km | ≤ 0.2 |

| Cut-off Wavelength λcc | - | nm | ≤ 1260 |

| Mode Field Diameter (MFD) | 1310 nm | μm | 9.2±0.4 |

| 1550 nm | μm | 10.4±0.5 | |

| Attenuation Discontinuity | 1310 nm | dB | ≤ 0.03 |

| 1550 nm | dB | ≤ 0.03 | |

| Geometrical | |||

|

Cladding Diameter |

μm |

125±0.7 |

|

|

Cladding Non-Circularity |

% |

≤ 1.0 |

|

|

Core/Cladding Concentricity Error |

μm |

≤ 0.5 |

|

|

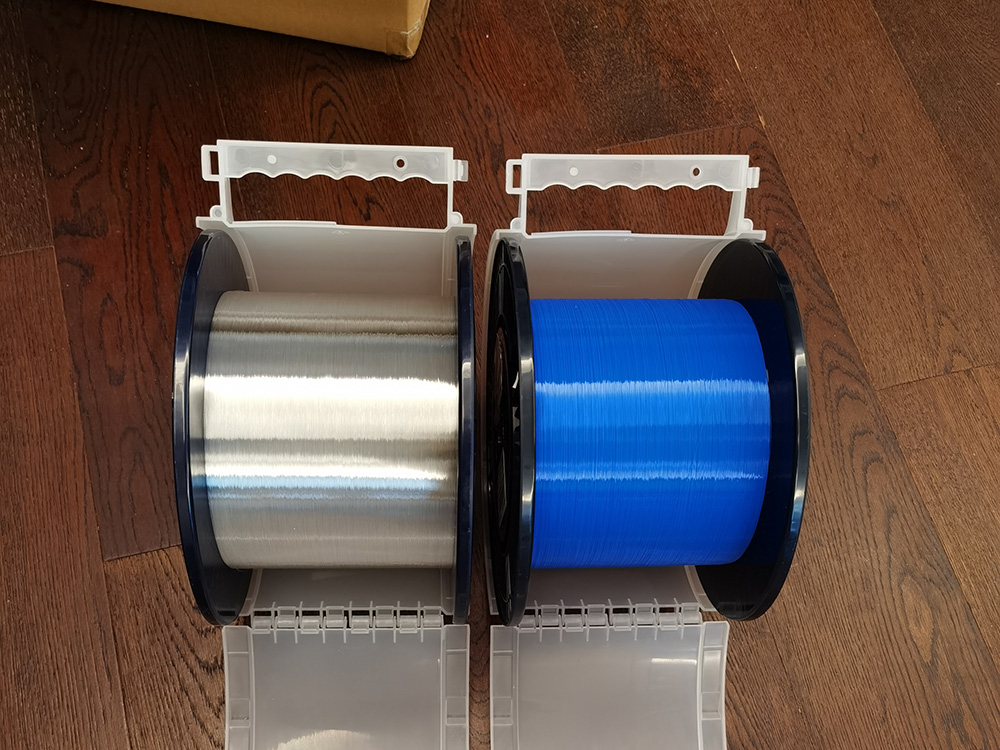

Coating Diameter (Uncolored) |

μm |

242±7 (standard) |

|

|

μm |

200±10 (optional) |

||

|

Coating/Cladding Concentricity Error |

μm |

≤ 12 |

|

|

Curl |

m |

≥ 4 |

|

|

Environmental (1310nm, 1550nm) |

|||

|

Temperature Cycling |

-60℃ to +85℃ |

dB/km |

≤ 0.05 |

|

High Temperature & High Humidity |

85℃, 85% RH, 30days |

dB/km |

≤ 0.05 |

|

Water Immersion |

23℃, 30days |

dB/km |

≤ 0.05 |

|

High Temperature Aging |

85℃, 30days |

dB/km |

≤ 0.05 |

|

Mechanical |

|||

|

Proof Stress |

- |

GPa |

0.69 |

|

Coating Strip Force * |

Peak |

N |

1.3 - 8.9 |

|

Average |

N |

1.0 - 5.0 |

|

|

Tensile Strength |

Fk=50% |

GPa |

≥ 4.00 |

|

Fk= 15% |

GPa |

≥ 3.20 |

|

|

Dynamic Fatigue (Nd) |

- |

- |

≥ 20 |

|

Macrobending Loss |

|||

|

Ø30 mm×10 t |

1550 nm |

dB |

≤ 0.25 |

|

1625 nm |

dB |

≤ 1.0 |

|

|

Ø20 mm×1 t |

1550 nm |

dB |

≤ 0.75 |

|

1625 nm |

dB |

≤ 1.5 |

|

|

* The peak peel force of the coating is 0.6-8.9N, and the average value is 0.6-5.0N when the coatingdiameter is 200±10. |

|||