Semi-Dry ADSS Cable ADSS-PE-6/8/12/24/48/96/144B1.3 (80m installation span)

Optical fiber (ITU-T G.652D)

Characteristics |

Units |

Specified values |

|

Optical characteristics | |||

Type of fiber |

Single mode, Doped silica |

||

Attenuation |

@1310nm @1550nm @1625nm |

dB/km |

≤0.36 ≤0.23 ≤0.25 |

Dispersion coefficient |

@1288- 1339nm @1550nm @1625nm |

ps/(nm.km) |

≤3.5 ≤18 ≤22 |

Zero dispersion wavelength |

nm |

1300~1324 |

|

Zero dispersion slope |

ps/(nm2.k m) |

≤0.092 |

|

|

Polarization Mode Dispersion PMD Maximum Individual Fibre PMD Link Design Value |

ps/km1/2 |

≤0.2 ≤0.15 |

|

Cable Cut-off wavelength λcc |

nm |

≤1260 |

|

Mode field diameter (MFD) @1310nm |

μm |

9.2±0.4 |

|

Geometrical characteristics | |||

Cladding diameter |

μm |

125.0±0.7 |

|

Cladding non-circularity |

% |

≤1.0 |

|

Coating diameter (primary coating) |

μm |

245±10 |

|

Coating/Cladding concentricity error |

μm |

≤12.0 |

|

Core/cladding concentricity error |

μm |

≤0.6 |

|

Curl (radius) |

m |

≥4 |

|

Mechanical characteristics | |||

Proof test offline |

N % kpsi |

≥8.4 ≥1.0 ≥100 |

|

Bending Dependence Induced Attenuation 100 turns, 60mm diameter @1625nm |

dB |

≤0.1 |

|

Temperature Dependence Induced Attenuation @ 1310 & 1550nm -60℃~ +85℃ |

dB/km |

≤0.05 |

|

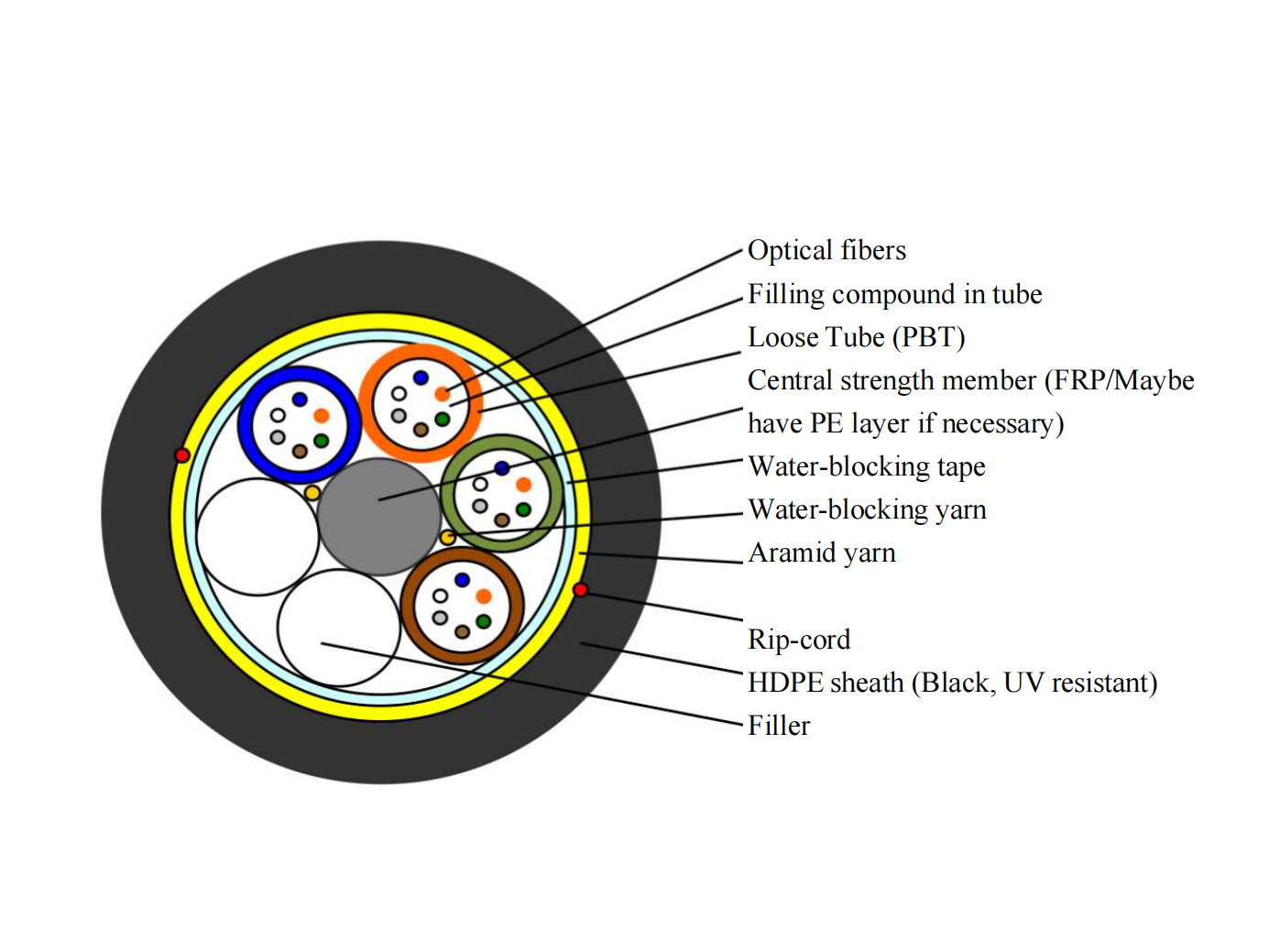

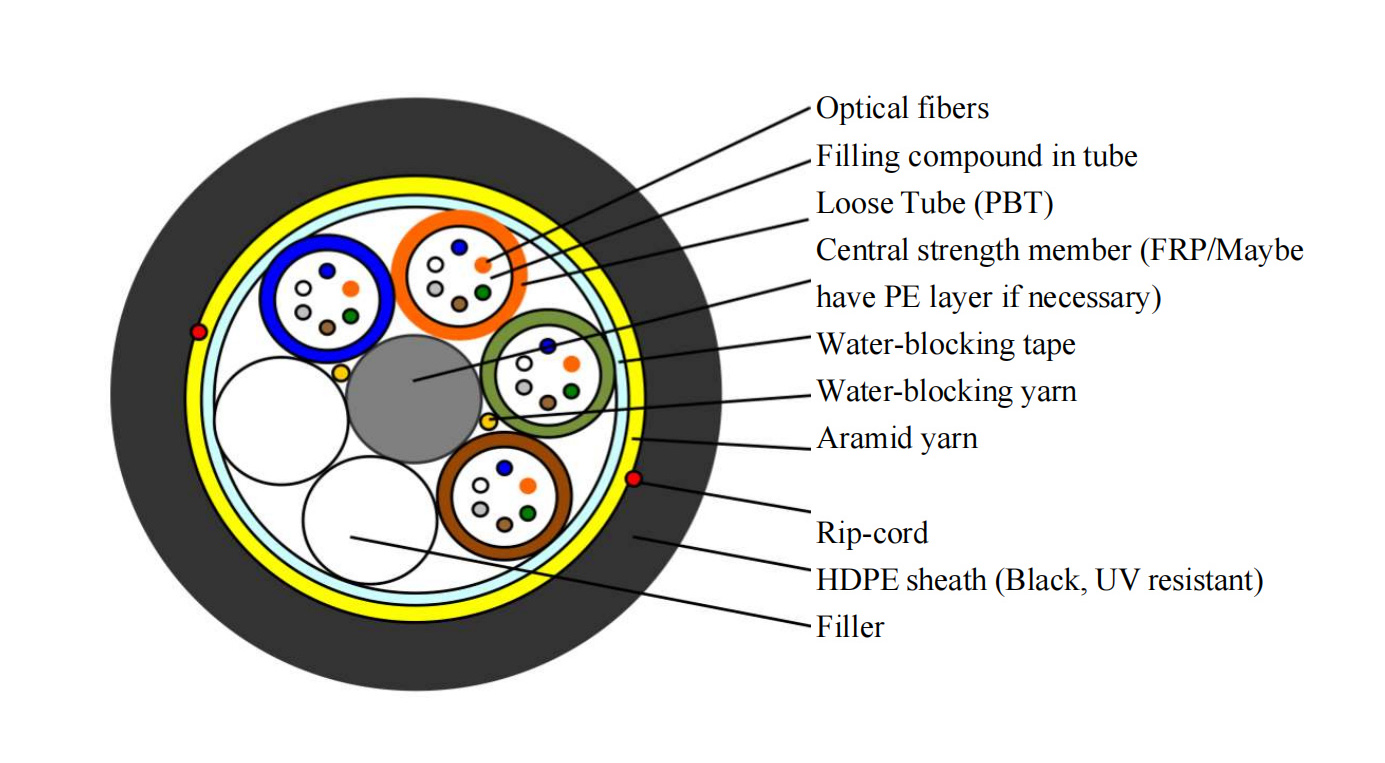

Cross-sectional drawing of cable

Identification of fibers and loose buffer tubes

NO. |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

Tube color |

Blue |

Orange |

Green |

Brown |

Gray |

White |

Red |

Black |

Yellow |

Purple |

Pink |

Aqua |

6F |

6B1.3 |

Filler |

Filler |

Filler |

Filler |

Filler |

/ |

/ |

/ |

/ |

/ |

/ |

8F |

4B1.3 |

4B1.3 |

Filler |

Filler |

Filler |

Filler |

/ |

/ |

/ |

/ |

/ |

/ |

12F |

6B1.3 |

6B1.3 |

Filler |

Filler |

Filler |

Filler |

/ |

/ |

/ |

/ |

/ |

/ |

24F |

6B1.3 |

6B1.3 |

6B1.3 |

6B1.3 |

Filler |

Filler |

/ |

/ |

/ |

/ |

/ |

/ |

48F |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

Filler |

Filler |

/ |

/ |

/ |

/ |

/ |

/ |

96F |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

/ |

/ |

/ |

/ |

144F |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

12B1.3 |

Color code of fibers: blue, orange, green, brown, gray, white, red, black, yellow, violet, pink and aqua. | ||||||||||||

Main mechanical performance of cable

Cable Type |

Tension (MAT, N) |

Crush (N/100mm) |

|

Short term |

Long term |

||

ADSS-PE-6~144B1.3-80m |

2500 |

1000 |

300 |

Diameter and Weight of Cable

Cable Type |

Outer Diameter (±5%) mm |

Approx. Weight kg/km |

ADSS-PE-6/8/12/24B1.3-80m |

9.8 |

72 |

ADSS-PE-48B1.3-80m |

10.6 |

86 |

ADSS-PE-96B1.3-80m |

12.0 |

112 |

ADSS-PE-144B1.3-80m |

14.8 |

170 |

Physical Mechanical and Environmental Performance and Tests

Test |

Standard |

Specified value |

Acceptance criteria |

Tension |

IEC 60794-1-21E1 |

Length of test: ≥50m; Load: See Sec.3.2; Duration: 1 min. |

After test, additional attenuation: ≤0.1dB; No damage to outer jacket and inner elements. |

Crush |

IEC 60794-1- 21E3A |

Load: See Sec.3.2; Duration: 1 min. |

After test, additional attenuation: ≤0.1dB; No damage to outer jacket and inner elements. |

Impact |

IEC 60794-1-21E4 |

Radius: 300 mm; Impact energy: 10 J; Impact number: 1; Impact points: 3. |

After test, additional attenuation: ≤0.1dB; No damage to outer jacket and inner elements. |

|

Repeated bending |

IEC 60794-1-21E6 |

Diameter of pulley: 20×OD; Number of bends: 25 times; Load: 150N. |

After test, additional attenuation: ≤0.1dB; No damage to outer jacket and inner elements. |

Torsion |

IEC 60794-1-21E7 |

Axial Load: 150N; Length under test: 1m; Cycles: 10; Angle of rotations: ±180° . |

After test, additional attenuation: ≤0.1dB; No damage to outer jacket and inner elements. |

Temperature cycling |

IEC 60794-1-22F1 |

-20℃~+60℃, 2 cycles, 8h |

The change in attenuation coefficient shall be less than 0.1 dB/km. |

|

Water penetration |

IEC 60794-1-22F5 |

Sample 3m, water 1m, 24h |

No water leakage. |

Length marking