Semi-dryADSS Armored & Anti-Rodent Cable (Double Jacket) ADSS-PE-72B1.3-200m

Optical fiber (ITU-T G.652D)

| Characteristics | Unit | Specified values |

| Optical characteristics | ||

| Type of fiber | Single mode, Doped silica | |

| Attenuation @1310nm @1550nm | dB/km | ≤0.36 ≤0.22 |

| Dispersion coefficient @1288-1339nm @1550nm @1625nm | ps/(nm.km) | ≤3.5 ≤18 ≤22 |

| Zero dispersion wavelength | nm | 1300~1324 |

| Zero dispersion slope | ps/(nm2.km) | ≤0.092 |

| Polarization Mode Dispersion PMD Maximum Individual Fibre PMD Link Design Value | ps/km1/2 | ≤0.2 ≤0.1 |

| Cable Cut-off wavelength λcc | nm | ≤1260 |

| Mode field diameter (MFD) @1310nm | μm | 9.2±0.4 |

| Geometrical characteristics | ||

| Cladding diameter | μm | 125.0±1.0 |

| Cladding non-circularity | % | ≤1.0 |

| Coating diameter (primary coating) | μm | 245±10 |

| Coating/Cladding concentricity error | μm | ≤12.0 |

| Core/cladding concentricity error | μm | ≤0.6 |

| Curl (radius) | m | ≥4 |

| Mechanical characteristics | ||

| Proof test offline | N % kpsi | ≥8.4 ≥1.0 ≥100 |

| Bending Dependence Induced Attenuation 100turns, Φ60mm @1625nm | dB | ≤0.1 |

| Temperature Dependence Induced Attenuation @ 1310 & 1550nm, -60℃~ +85℃ | dB/km | ≤0.05 |

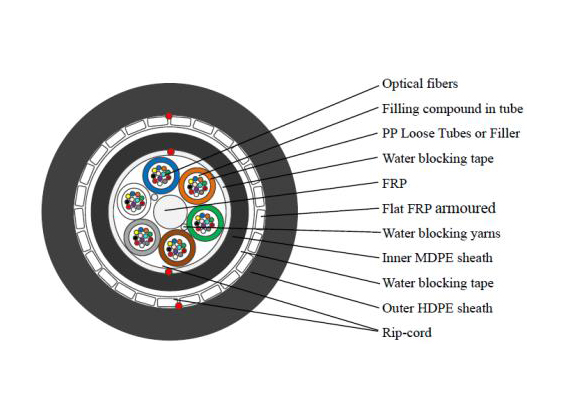

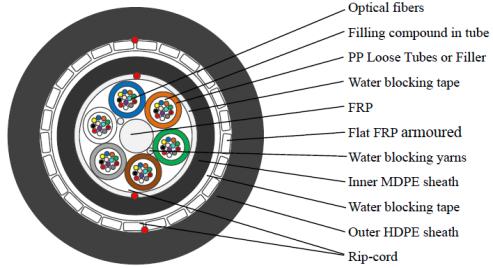

Cross-sectional Drawing of Cable

Identification of Fibers and loose tubes

The color code of the loose tubes and the individual fibers within each loose tubeshall be in accordance with below:

| No. of loose tube | 1 | 2 | 3 | 4 | 5 | 6 |

| Color code of loose tube | Blue | Orange | Green | Brown | Gray | White |

| ADSS-PE-72B1.3-200m | 12B1.3 | 12B1.3 | 12B1.3 | 12B1.3 | 12B1.3 | 12B1.3 |

| Color code of fibers: blue, orange, green, brown, gray, white, red, black, yellow, violet, pink and aqua. | ||||||

Main mechanical performance of cable

| Cable Type | Sag (%) | Tension ( N) | Crush (N/100mm) | ||

| Short term | Long term | Short term | Long term | ||

| ADSS-PE-72B1.3-200m | 1.5 | 5500 | 1700 | 2200 | 1000 |

Diameter and Weight of Cable

| Cable Type | Tube Diameter (±8%) mm | Outer Diameter (±5%) mm | Approx. Weight (±5%) kg/km |

| ADSS-PE-72B1.3-200m | 2.4 | 15.2 | 200 |

| Inner Sheath Thickness: MDPE, 1.0±0.3 mm; Outer Sheath Thickness: HDPE, 1.8±0.3 mm; Armored flat FRP: 0.7mm*3mm, 9~11 pieces. | |||

Physical Mechanical and Environmental Performance and Tests

| Test | Standard | Specified value | Acceptance criteria |

| Tension | IEC 60794-1- 21-E1 | Length of test: ≥50m Load: see clause 3.2 Duration: 1 min | Fiber strain ≤ 0.6%, after test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Crush | IEC 60794-1- 21-E3A | Load: see clause 3.2 Duration: 1 min | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Impact | IEC 60794-1- 21-E4 | Energy of impact: 1000g Height of impact: 1m Number of impacts: at least 3 times | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Torsion | IEC 60794-1- 21-E7 | Axial Load: 150N Length under test: 1m Cycles: 10 Angle of rotations: ±90° | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Temperature cycling | IEC 60794-1- 22-F1 | -30℃~+70℃, 2 cycles, 12h | Δα≤0.1dB/km. |

| Water penetration | IEC 60794-1-22 F5B | Sample 3m, water 1m, 24h | No water leakage (Except Flat FRP armor layer). |

| Temperature range | Operation/Storage/Transportation | -30℃~+70℃ | |

| Installation | -10℃~+60℃ | ||

| Installation conditions | NESC | Light | |

| Cable bending radius | Static | 15×OD | |

| Dynamic | 25×OD | ||

Physical Mechanical and Environmental Performance and Tests

| Test | Standard | Specified value | Acceptance criteria |

| Tension | IEC 60794-1- 21-E1 | Length of test: ≥50m Load: see clause 3.2 Duration: 1 min | Fiber strain ≤ 0.6%, after test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Crush | IEC 60794-1- 21-E3A | Load: see clause 3.2 Duration: 1 min | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Impact | IEC 60794-1- 21-E4 | Energy of impact: 1000g Height of impact: 1m Number of impacts: at least 3 times | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Torsion | IEC 60794-1- 21-E7 | Axial Load: 150N Length under test: 1m Cycles: 10 Angle of rotations: ±90° | After test, no attenuation change, no fiber breakage and the cable sheath shall not be cracked. |

| Temperature cycling | IEC 60794-1- 22-F1 | -30℃~+70℃, 2 cycles, 12h | Δα≤0.1dB/km. |

| Water penetration | IEC 60794-1-22 F5B | Sample 3m, water 1m, 24h | No water leakage (Except Flat FRP armor layer). |

| Temperature range | Operation/Storage/Transportation | -30℃~+70℃ | |

| Installation | -10℃~+60℃ | ||

| Installation conditions | NESC | Light | |

| Cable bending radius | Static | 15×OD | |

| Dynamic | 25×OD | ||

Length marking

The sheathshall be marked with white characters at intervals of one meter with following information. Other marking is also available if requested by customer.

1) Length marking

2) Cable type and fiber counts

3) Name of the manufacturer

4) Year of manufacture

5) Information requested by customer

For example

Cable packing

1. Each length of the cable shall be wound on a separate reel. Standard length of cable shall be 4000m, other cable length is also available if requested by customer.

2. Both ends of the cableshall be sealed with suitable plastic caps to prevent the entry of moisture during shipping, handling and storage, and the A-end shall be indicated with red cap, the B-end shall be indicated with green cap. The cable ends shall be securely fastened to the reel. At least 1.5 meter of the cable inner end shall be remained for test purpose.

3. The cable reelshall be iron-wooden materials. It is not exceeding 2.4 meters in diameter and 1.6 meters in width. The diameter of the center hole is less than 110mm, and the reelshall be protected the cable form the damage during shipping, storage and installation.

4. The cable reel is sealed with strip planks to ensure that the cable will not be damaged during transportation.

5. Details given below shall be distinctly marked with a weatherproof materials on the reel flange, at the same time, a Quality Certification and a Test Record shall be provided with the reel when it is delivered.

(1)Purchaser’s Name

(2)Cable type and fiber counts

(3)Length of cable in meters

(4)Gross weight and in kilograms

(5)Name of the manufacturer

(6)Year of manufacture

(7)Arrow showing the direction the reelshall be rolled

(8)Other shipping mark is also available if requested by customer.

6. Information of cable reel (completely fumigated wooden reel, picture as below):

| Reel length (Km) | Size (Flange Diameter * Width) (mm) | Approx. Weight (Kg/Km) |

| 4.0+5% | 1550*1100 | 160.00 |

7. Picture of completely fumigated wooden reel: